17 small Oregon food and beverage manufacturing companies participated in a Food Safety Cohort, led by OMEP Senior Consultants Linda Wechsler and Michelle Knepel.

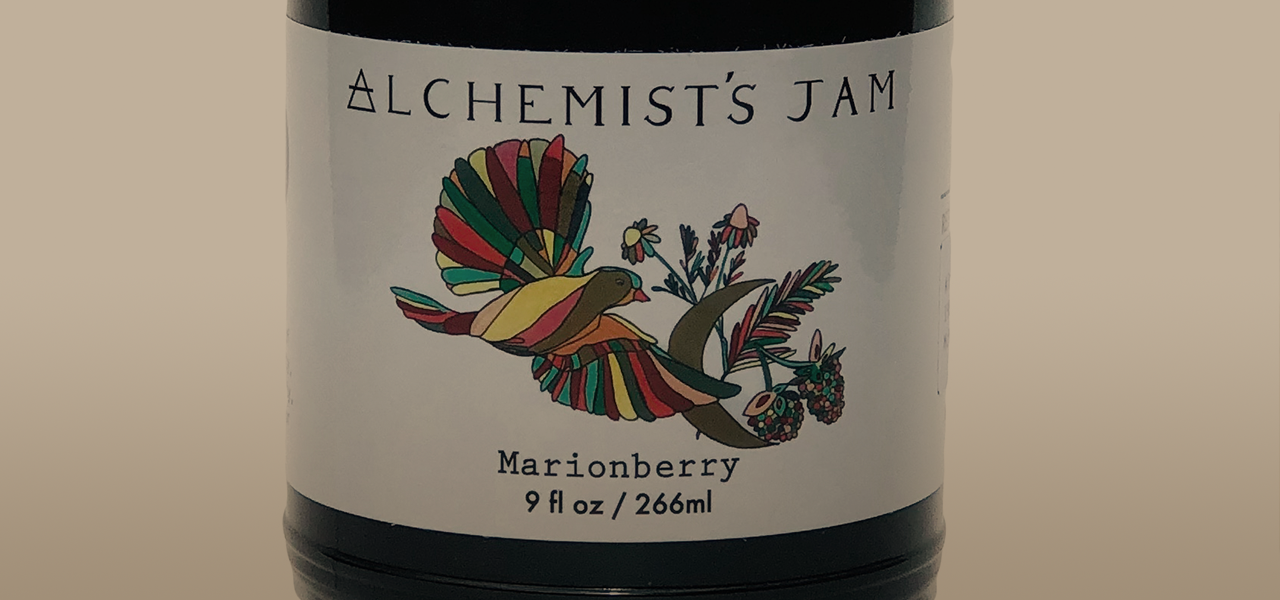

Participating companies included Alchemist’s Jam, Bagel Sphere, Blue Lotus Chai Company, Divine Distillers, Elegant Elephant Fine Foods, Food for the Sole, For Bitter for Worse, Fresh N Local Foods, Hot Winter Hot Sauce, Kester Foods, Ninkasi Brewing, PDX Empanadas, Positive Community Kitchen, Screamin’ Jay’s Hot Lunch, Thai and True, WildRiver, and Young Mountain Tea.