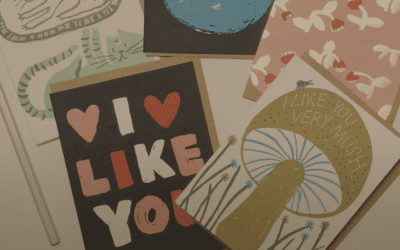

Since 1999, Egg Press has been creating original, inspiring, handcrafted letterpress greeting cards and lifestyle products that connect and enrich people’s lives. As one of the few pioneers driving the resurgence of letterpress printing as an art form, they have established our leadership position within the industry as well as within the handcraft movement.

Tess Darrow started Egg Press in Portland, Oregon as an outlet to combine her passion for graphic design with her degree in textile design from the University of Washington, where she began letterpress printing. In 1999, she left her product and brand design career at Nike to devote herself fully to building Egg Press. In addition to their consumer products business, Egg Press works on specialized communications projects and custom printing for individuals and businesses — from multi-national companies like Herman Miller, MoMA, Nike, Adidas, and Apple to local design-oriented companies like Ace Hotel and Schoolhouse Electric to boutique wedding designers. Egg Press’ team is adept at maintaining our creative entrepreneurial spirit while understanding the product creation timelines of companies of all shapes and sizes.