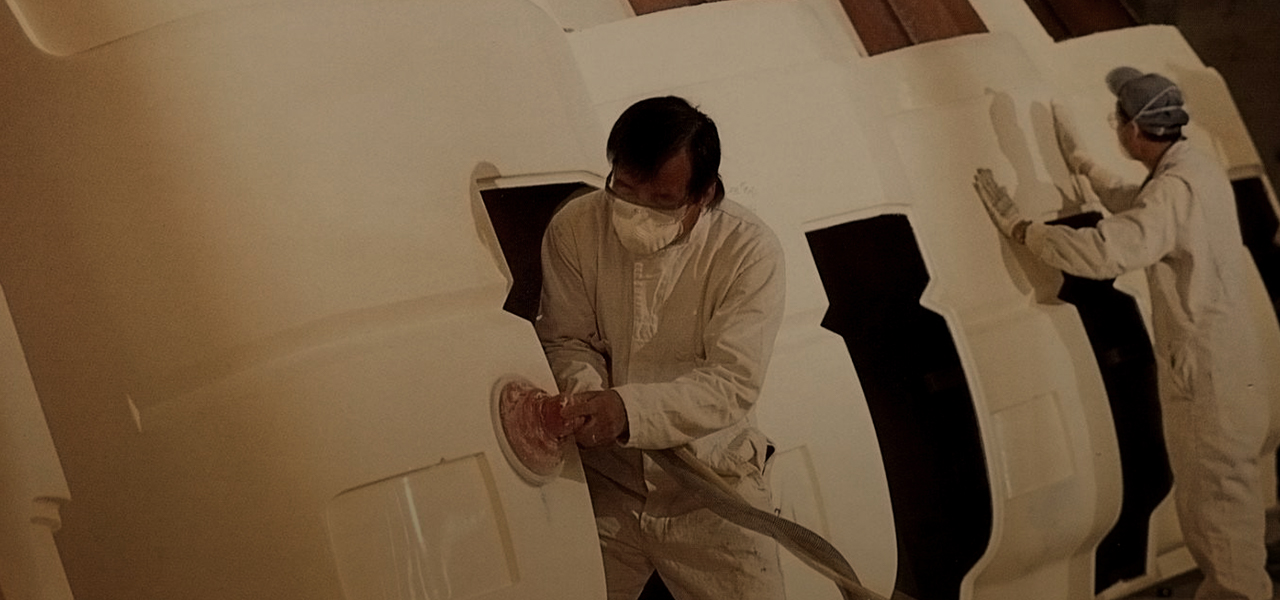

Miles Fiberglass and Composites (MFC) is a family owned corporation with plants in Oregon City and Portland Oregon. MFC employs 73 people between the 2 plants with approximately 55 production employees. Due to their commitment to their workforce and community, MFC as part of their growth strategy made the resolution to invest in MFC employee development to ensure a strong and vibrant future.

Success Story

Miles Fiberglass and Composites

Industry

Location

Date Founded

Number of Employees

Background

$4M Additional Sales

6 Jobs Created

$840,000 Cost Savings

The Situation

Because of their growth projections, as well as a recent influx of new hires MFC sought improvement opportunities related to workforce training and development. OMEP has worked with MFC on a variety of efforts over the years. Near the end of 2015, OMEP and MFC partnered specifically to prototype a new smart talent training approach developed by OMEP.

The Solution

In 2015, MFC and OMEP collaborated to implement the SMART Talent approach. They embraced the idea that, “The only sustainable competitive advantage is an organization’s ability to learn faster than the competition.” Peter M. Senge

First, OMEP and MFC broke down all duties of several key production positions into individual action steps. Action steps were then organized into learning modules that employees use to train other workers. Certain employees then become organizational trainers through specific train-the-trainer classes, utilizing adult learning theories. This is known as Structured On the Job Training (SOJT).

In parallel with SOJT, MFC worked with OMEP to build development pathways for employees. This enabled MFC staff to become proficient quickly and new hires to be quickly absorbed. At the onset of the program, an employee had worked for 10 months in one area without being trained for any other tasks. After establishing the in-house training program, that employee was able to work in a different department after a few hours of coaching. Additionally, another new hire decided to stay at MFC rather than go to another employer because they saw the commitment of MFC to their employees and a clear path to move upward within the company.

As the training continues to be developed, Miles has also embraced the concept of building a learning culture in their business. Rather than compensating employees based on longevity, Miles has successfully eliminated reviews that were based on subjective evaluations, moving to a true compensation based on skills and knowledge of their staff. Instituting a “learn to earn” compensation system results in a more engaged, proficient, and competitive workforce. In addition, MFC has had a tangible reduction in rework, continues to retain talent, and is accomplishing more with their current staff due to cross training.

The Results

MFC has seen outstanding results since embracing the Smart Talent approach. Some of the results are listed below:

- By creating a pool of more proficient workers, MFC was able to take on $4,000,000 in additional sales and retain $250,000 of existing client sales.

- 6 jobs created and 5 jobs retained.

- 840,000 cost savings through a reduction in training time, reduced rework, and streamlined operations.

MFC has been at the leading edge of the Smart Talent journey and will be continuing to integrate Smart Talent into their operations.

Get in touch with an OMEP Consultant Today!

TALK TO US

One of the best attributes OMEP has is their deep understanding of working with manufacturers. They know the challenges manufacturers face in keeping production running while at the same time working to make production better.